†Mechanical Machine Design

†Mechanical Machine Design

Right from the

beginning I was intimidated by this project. None of my group nor I were aware

we needed the Gestalt boards. So it came as a big surprise when we heard we were

supposed to use them exclusively to control our group project. As soon as were

heard this, we asked Neil if it would be okay to use an Arduino gshield

instead. He said that was acceptable as long as we wrote our own code. Having

cleared that up, we got to work. We decided to create a 2-axis machine that

could trace the motion of a pen drawing on a tablet. Our original idea was to

have our machine move around with an old 3-Doodler we had laying around. The

3-Doodler needed some attention if we were going to use it, as it had stopped

working a while ago. Fortunately it was an easy fix, a wire had come loose from

the board. Thanks to my newly acquired soldering skills the doodler was working

in a jiffy. We ended up not using the 3D  doodler though, as it does not produce a steady stream of plastic

reliably.

doodler though, as it does not produce a steady stream of plastic

reliably.

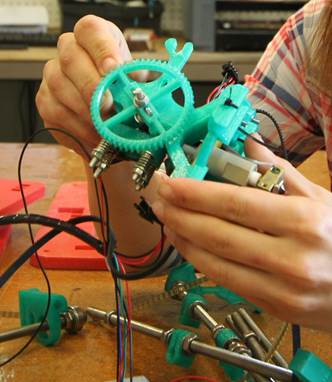

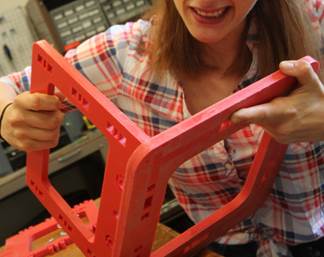

†I also disassembled two CNC machines for this

project, an old MTM snap from a previous fab academy course, and a reprap 3D

printer, specifically a Durbie Prusa Mendel. Both were tricky to disassemble. I

had to use a variety of wrenches and pliers. I surprised myself by being able

to pull apart the MTM snap's thick plastic panels. Both machines had multiple

belts. Gabriel Ewing took over for me when I cut my finger on a sharp bit on

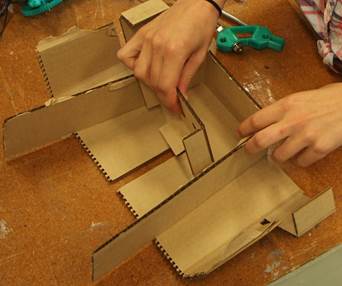

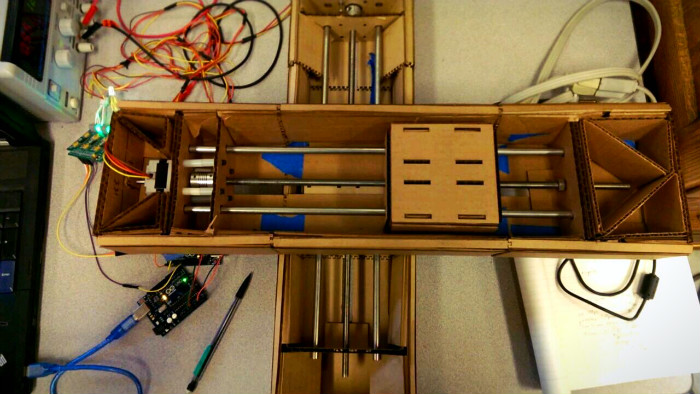

the Mendel. Virginia McCreary worked on obtaining the file to laser out our

cardboard. Cardboard is a very useful thing to have around, fortunately we keep

lots of it in the lab for various prototyping. We all took a stab at assembling

the cardboard housing.† Then I built the

second stage, taking care to fold over the cardboard bits so it would be

secure. Virginia had some great pointers, such as using hot glue to stabilize

the stages. Our cardboard was not the recommended thickness so it didnít fit

seamlessly at first. Once it was assembled with parts from the old 3D printers,

I checked up on my mates to see what sort of progress they had made creating a

code to move the stepper motors. They had wired the stepper motor to the

gshield and 3 wires to the Arduino Uno to the gshield, one for direction, one

for step signal, and one for enabling. I learned that this was a simple

process, as enabling drivers can be done by setting pin 8 to ground. This is  represented in code as "digitalWrite 8,

LOW". The stepper's direction is decided by the high or low voltage on the

direction pin. Jeff Putney completed an I2C code to send commands to the

Arduino Uno, by figuring out how to enable to the General Call! This discovery

had yet to been included in the I2C Arduino libraries! The ATmega has support

for the I2C, but is represented as its Two Wire Interface. To enable the

General call, we had to insert this code:

represented in code as "digitalWrite 8,

LOW". The stepper's direction is decided by the high or low voltage on the

direction pin. Jeff Putney completed an I2C code to send commands to the

Arduino Uno, by figuring out how to enable to the General Call! This discovery

had yet to been included in the I2C Arduino libraries! The ATmega has support

for the I2C, but is represented as its Two Wire Interface. To enable the

General call, we had to insert this code:

TWAR

= 0x03;

With

this valuable code, we were able to send instructions to each Arduino

individually, then direct them to start moving altogether. Each node can

receive a couple of instructions; individual

control, speed, direction, and number of steps, and the other is the synchronized move  command that makes all nodes move at once.

command that makes all nodes move at once.  Finally, Colten Jackson modified a processing example

to create an interface to easily control the machine. This code is quite neat

in that you can draw with a stylus onto a pad, and the x & y coordinates of

the line were read by the machine as a new position for the stepper motors to

go. Here is a video of

the project! The end result worked, but it could have worked better.† If we were to improve upon this design we

would do two things. One, queue multiple instructions, so there would be no

pausing between commands, and two, add feedback to the node so we would have a

smarter machine all around.

Finally, Colten Jackson modified a processing example

to create an interface to easily control the machine. This code is quite neat

in that you can draw with a stylus onto a pad, and the x & y coordinates of

the line were read by the machine as a new position for the stepper motors to

go. Here is a video of

the project! The end result worked, but it could have worked better.† If we were to improve upon this design we

would do two things. One, queue multiple instructions, so there would be no

pausing between commands, and two, add feedback to the node so we would have a

smarter machine all around.